Brickwork in the Land of Palms

- Arts

- Architecture

Written and photographed by Jeff Koehler

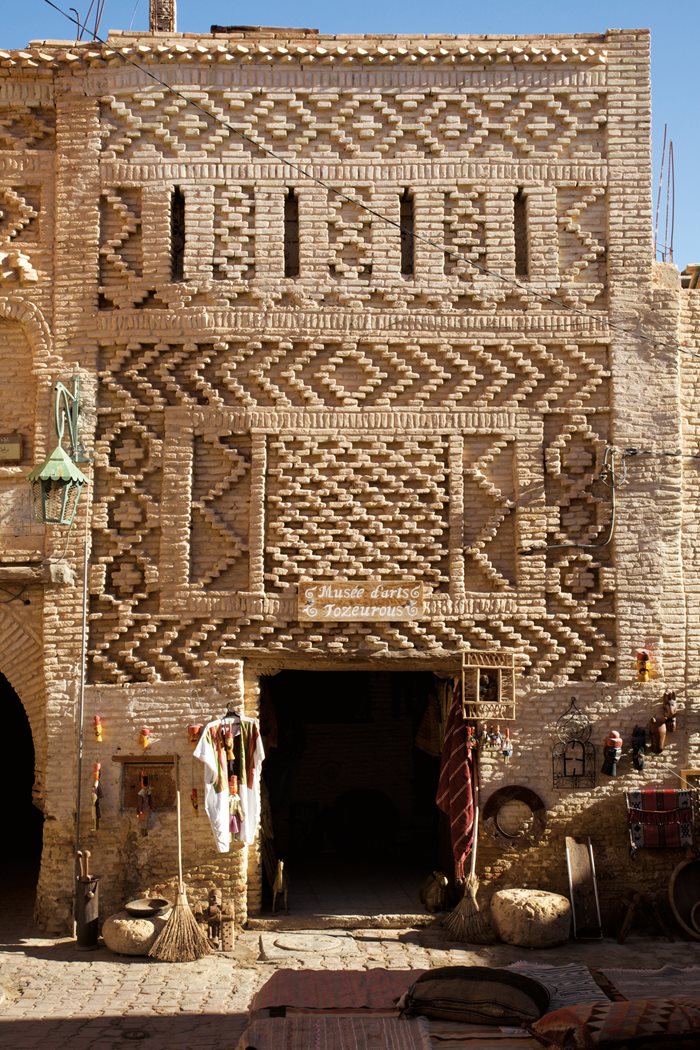

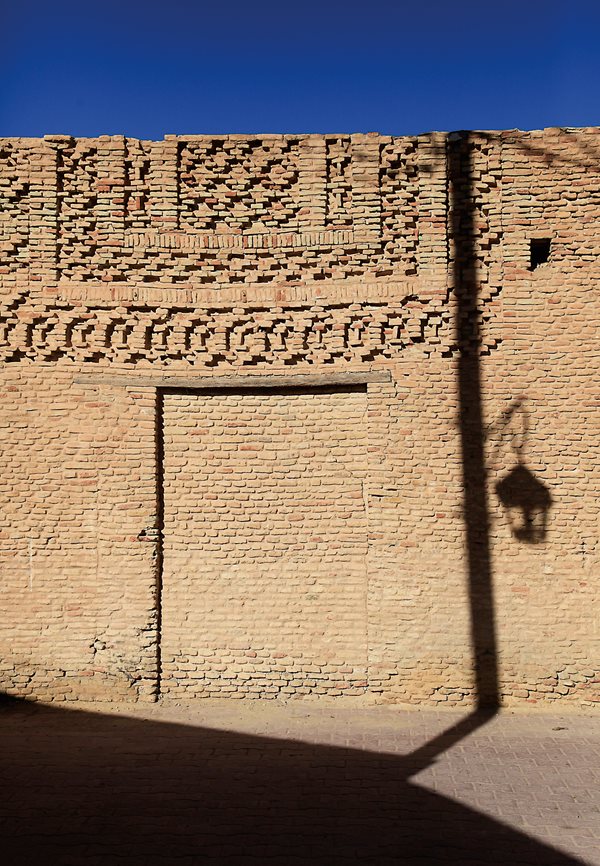

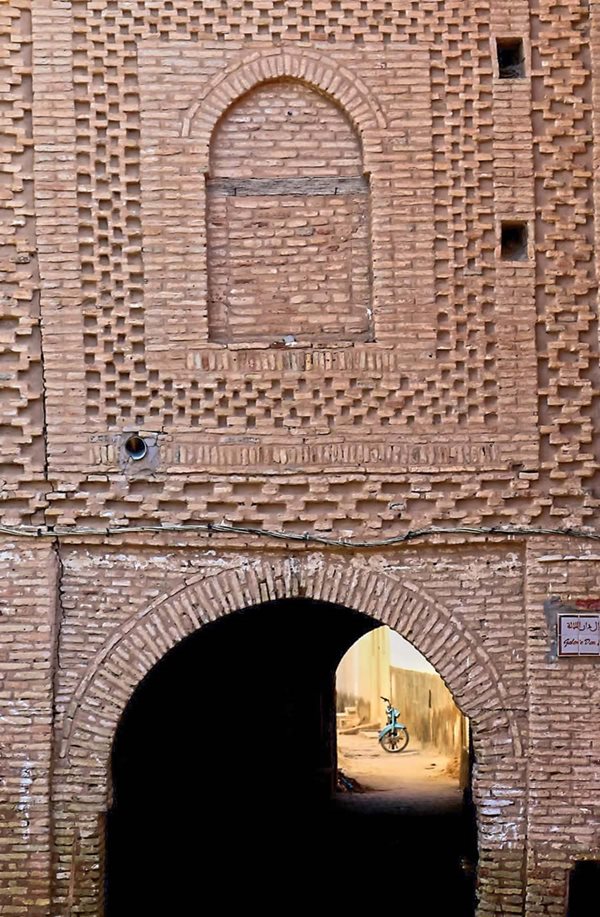

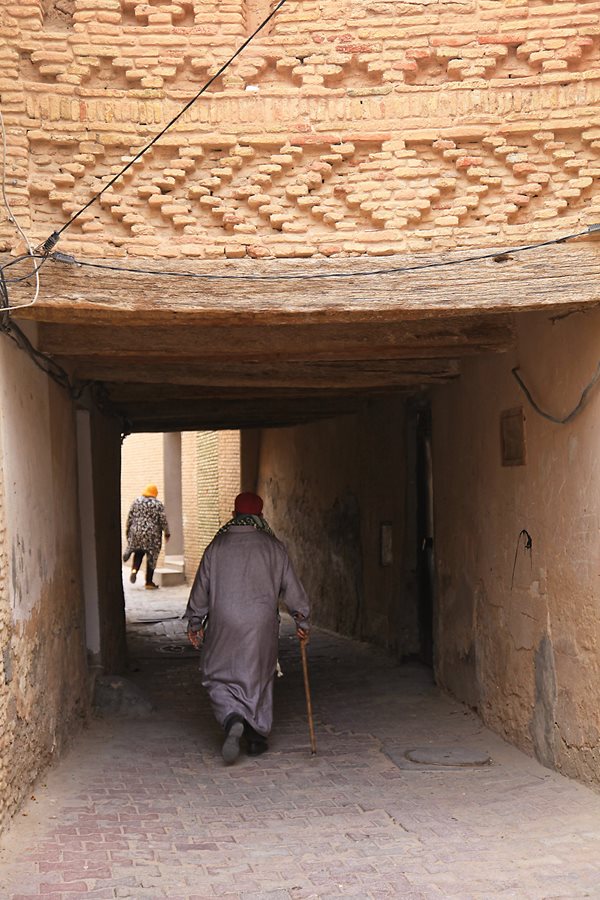

The narrow lane passed under a vaulted passageway and emerged back into the bright sunshine as it wound through Tozeur’s Ouled el-Hadef quarter. The houses in this centuries-old neighborhood open privately onto interior courtyards, offering the narrow streets only tall exterior walls with high, slitted windows and stout doors made of palm wood. The walls, though, are not smooth and whitewashed as in much of the country. Protruding and receding bricks form intricate geometrical patterns around windows, above doors and on many of the walls, creating contrasts of light and shadows.

Standing at a distance from a smattering of earthen, brick mosaics in this Tunisian southern city, the walls come alive in patterns, dancing and shape-shifting in the light of midday. In the fore, the small bricks appear bland, yellowish-green, and unadorned. But one only needs to move back a few steps and put distance between their eyes and the 15th-century Berber edifices to relish the complexity of the intricate masonry emerging from the walls.

Amid the Sahara, Tozeur’s famed brick mosaics are as celebrated as the town’s safari excursions, sunset camel rides and guided tours to the nearby Star Wars sets of Tatooine, the fictional original home of the movie’s hero, Luke Skywalker. But the bricks, arranged in their many unique geometric patterns—they delight the residents and tourists alike.

“They’re beautiful,” Tozeur resident Imed Chorfi says, gazing at the familiar walls.

Motioning to a row of inverted Vs situated across the top of an archway in the mosaic, he says, “This is a camel train.” He then points out stylized palm trees and a zigzagging snake design.

“We represent what is around us.”

Only a small number of brick artisans remain, keeping alive a tradition of brickmaking that hasn’t changed much through the centuries. Chorfi has seen the local artisans using the same method of brick creation and design as the town’s Berber predecessors did, including setting afire the abundance of fronds from the local date palm orchards, which are used to fuel the brickmaking ovens. Tozeur became prosperous through its plenty of dates, even referenced by 11th-century Andalusian historian and geographer al-Bakri, who wrote: “There is no other place in Ifrikiya that produces so many dates; almost every day a thousand camels, or even more, are loaded with this fruit.”

Today the date orchards of Tozeur, or palmeraie, spread some 15 square kilometers and contain 400,000 palms, famous for their amber-colored, near-translucent dates, or deglet nour. The region is known as the “Land of the Palms,” or in Arabic, Bled el-Djerid. Without the numerous palms, the brick ovens could not burn—the bricks could not be.

Antar Chorba, an eighth-generation Tozeur brickmaker, is from one of the families in the region that continues the tradition of the early brick masons. Chorba explains that structures erected in the Djerid, or southwest region of Tunisia, in the early days were originally made of sun-dried bricks, molded of mud and straw, and in Arabic called fankar. The clay was dry enough to be cut into blocks, he says, but was vulnerable to the powerful rainstorms that often swept the area. The fankar also tended to erode from wind and sandstorms and the intense heat of the Saharan sun. Soon locals began experimenting with firing the clay in handmade kilns, which overtime the masons observed improved durability. Baked bricks were a response to what the Berbers and the desert lacked—stone—but also what they had in abundance: clay-rich soil, water from 200 natural springs, and ample fuel from the cut palm fronds. Simply explained, Chorba says, “because there were no quarries.”

As in the tradition of those who came before him, Chorba uses two types of soil to prepare the bricks: a reddish clay, which is excavated near El Hamma, about eight kilometers away from the city, and a lighter shade of sand-like mix brought from an area near the brickworks. Put into a bathtub-size trough, the soils are sunk to absorb water for 12 hours before being mixed by hand into a paste.

Working quickly, Chorba can form over 600 bricks a day. With the paste ready, he scatters ash from the kiln across a patch of courtyard. This prevents sticking and absorbs moisture. He then sets a simple bottomless wooden mold on the ground and works a handful of clay into one of the rectangular holes until there are no air bubbles. He then repeats the process to form more bricks. After filling a section of the courtyard he’s working on, he generously tosses more ash over the top of the freshly molded bricks. Along with blotting up excess moisture, the protective layer of ash stops cracks from forming on the surface of the bricks as they dry.

“In the summer, when the temperature is over over 45 degrees [Celsius], we can make them in the morning and be ready to stack them in afternoon,” says Chorba, mentioning in the winter bricks may take three or four days to complete.

While Chorba molds bricks, an assistant patiently scrapes with a knife each of the six sides of the bricks, which were formed a few days before, to remove the ash and give them their final shape. Then, the bricks are stacked in harsai, pillars of 10 or 12, allowing for ventilation as the bricks dry. This method also helps the masons keep count of production. At the final stage, they are stored until there are enough to fill the oven, which can hold between 10,000 and 20,000 bricks.

The open-top, updraft kilns measure upward of 3 meters, with a narrow, door-like gap for loading bricks. The fuel pit is subterranean and directly beneath the oven, and between the two parts of the kiln is a wheel-like chamber floor known as a sieve, an eight- or nine-spoke platform supported by vaulted arches. Loading takes four or five workers a full day to complete.

“Stacking needs to be done in a way that the heat can get to all the bricks,” Chorba says. Once the kiln has been filled, the loading gap is plugged with clay and the ovens set ablaze.

Nasri Chabani, another of Tozeur’s brickmakers, works in a nearby oven. He explains the importance of drying the clay molds before placing them in the ovens, “Drying is the most important step because if not done right the bricks will break in the kiln.”

As he feeds a 3-meter-long palm into a firing kiln, Chabani also mentions how the brick production in Tozeur has created an opportunity for date palm cleanup.

“It can be said that brickwork is the waste disposal industry created by the date industry,” he says, describing the annual trimming of palm trees which are then sold to the brickmakers for the kilns.

To fire a load of bricks, it takes around 6,000 fronds and 24 hours with temperatures inside the oven reaching nearly 1,000 degrees Celsius. It takes three to four days for the bricks to cool. Then the bricks are removed through the temporarily plugged loading door, which is broken open; each brick is then sorted.

Both Chorba and Chabani describe the original brickmaking process that took place centuries ago. In those early years, the masons pushed fired bricks into the adobe of each structure to protect the walls on the outside. But they soon discovered by using this method, it created a natural barrier from the sun’s heat, leaving the structures cooler inside. This region has the highest average temperature in Tunisia, and walls thickened with bricks helped insulate against extreme climate, Chorba says.

Deposits of clay and an abundance of palm fronds were not the only reasons local masons turned to using baked bricks in wall construction. They are highly durable, in part due to low density that allows them to absorb and expel water.

“It is also an extremely resistant material,” says Nidhal Hedfi, an engineer from Tozeur, explaining why the bricks rarely crack. “(A brick’s) low expansion rate allows it to withstand large thermal amplitudes.”

But the bricks also offered something else—decoration. Maghrib historian and professor at Université de Sousse Abdellatif Mrabet opined in his L’art de Bâtir au Jérid (The Art of Building in the Djerid), as an authority on the region’s architecture, the use of baked bricks as a “coating ensures a whole panoply of decorative patterns.” French historian, geographer, and traveler Augustine Bernard in 1924 was also beguiled by the bricks, describing a “checkerboard of the recessed bricks” with “all combinations of diamonds.”

For masons, the bricks were infused with possibilities. Placing them horizontally or vertically, lengthwise or crosswise, masons could coat facades to create decorations inspired by weaving, carpets and local motifs to achieve total originality.

“The solid bricks are meticulously arranged in a sort of ornamental grammar with the possibility of infinite combinations of decorative motifs,” Hedfi says, mentioning the local Berbers who were a likely source of the brick decor.

The decoration itself also added another level of protection from heat.

“The sets of recesses which characterize the arrangement of bricks allow the creation of minimal fractions of shadow on the entire facade, which minimizes the surface directly exposed to the sun’s rays and consequently reduces the heat that penetrates the wall,” Hedfi explains.

These gradually shifting patches of shade generate convection currents, lowering the surface temperature by creating a naturally ventilated wall. Hedfi’s observations are not merely based on his credentials as an engineer. He was born in Tozeur and spent his childhood in a traditional brick house.

Hedfi’s beloved Tozeur takes its name from the Latin Tusuros, bestowed by the Romans when they built a citadel fortress as part of their chain of fortified outposts meant to contain nomadic Berber populations, the original inhabitants of Tunisia. The city soon became a major trading post and important stopover for caravans traveling from the Sahara to the Tunisian coast, as well as those in transit to Makkah from the Maghrib region of Africa.

Tozeur’s antiquity and lasting importance through the centuries can still be seen in the city, through its kilns and brick mosaics. The city and its residents demonstrated technological sagacity even centuries ago. On Tozeur’s outskirts, where a bumpy dirt road opens toward the desert, some 35 cylindrical ovens jut up like large termite mounds. Beside each oven are smooth courtyards for molding and drying bricks with rudimentary frames of palm trunks that can be topped with fronds for shade, and a simple area to rest and store tools.

The lack of archeological digs makes it difficult to pinpoint when Tozeur shifted toward baked bricks. Oral tradition points towards Mesopotamia—including Iraq, but also parts of modern-day Iran and Syria, where a long-held tradition of ornate brick structures remain—somewhere between the 9th and 11th centuries.

Thirty minutes’ drive west of Tozeur, near the Algerian border, sits the town of Nefta, population 25,000. Mekki Khnissi, whose family has been making bricks there for 300 years, says it was settlers from Kufa, Iraq, who brought the tradition a millennium ago. “We still call it `Little Kufa,’” he says of the town.

Not everyone, though, is fully convinced. Mrabet says the brickmaking tradition could have begun before Islam arrived in Tunisia the seventh century.

“We talk about Iraq as well as Iran, but there is no more evidence there than to the contrary,” he says, pointing out a 2018 discovery near Tozeur of a late-Byzantine church, dating between the fifth and seventh centuries, with a north facade built of brick, and to a brick oven he discovered amid ruins of the ancient city of al-Halbah, which lies on the edge of Tozeur. The Djerid has long had a diverse population, drawing travelers, merchants, and, from the earliest days of Islam, pilgrims.

Equally ambiguous is why this beautiful and particularly effective architecture in such a hot, sunny climate is almost exclusively found in these two oases. Perhaps the prevalence of quarries in other areas, which did not offer an abundance of date palm fronds for fuel, allowed for differing variations of styles. Across the Algerian border, some buildings in two places—Tamacine and Tamellaht—do share similarities with the Tunisian towns, though. Mrabet surmises, “there is no doubt that Djeridian brick was exported to Tamacine and Tamellaht,” but the brickwork, he adds, shows a lack of mastery.

Until some 30 years ago, brickmaker Khnissi says Nefta’s kilns were in the center of town. Tunisian officials moved them because of pollution, and the large weekly suq now gathers on the flat expanse where they once stood. Before then, there were 20 families making bricks.

“Now there is just two. No one wants to do it. It’s tough,” Khnissi says.

Yet, the tradition of artisanal masonry continues in Tozeur and Nefta. New houses are erected using the bricks, and an area luxury hotel ordered 1 million of the bricks to use in its recent construction. Brickmaking is a cherished gem for those who grew up in the region, and those visiting for the first time. So, while tourists may come to experience the desert and its many timeless offerings, the bricks underscore the history of two towns and centuries of residents who have cemented their identity in the patterned facades of their homes.

You may also be interested in...

Meet Me at the Mudhif

History

Arts

Dozens of volunteers joined together in Houston, Texas, to construct a mudhif, a reed structure dating back 5,000 years to the Mesopotamian marshes of southern Iraq. To this day the hut serves as a town hall for Marsh Arabs to meet with their sheikh. In Houston, it also served as a meeting place--for some of the city's 4,000 Iraqis and their fellow Houstonians to share insights into an ancient society and gain a sense of community.

Escher + Alhambra = Infinity

Arts

Visits to Spain in 1922 and 1936 led Dutch artist M.C. Escher to discover the world of designs in Granada’s 13th-century Alhambra palace, where interlocking patterns in tiles and stucco on its walls and ceilings became springboards to ideas that shaped his art for the rest of his life.

The Bridge of Meanings

History

Arts

There is no truer symbol of Mostar, Bosnia-Herzegovina, than its Old Bridge. The magnificent icon of Balkan Islamic architecture was destroyed during the 1992–’95 war—but not for long. Like the multicultural workforce that produced the original hundreds of years earlier, a broad team of architects, engineers and others came together immediately to plan its reconstruction. This summer marked the 20th anniversary of the bridge’s reopening.